An Optimization-Centric Review on Integrating Artificial Intelligence and Digital Twin Technologies in Manufacturing

Published in Engineering Optimization, 2025

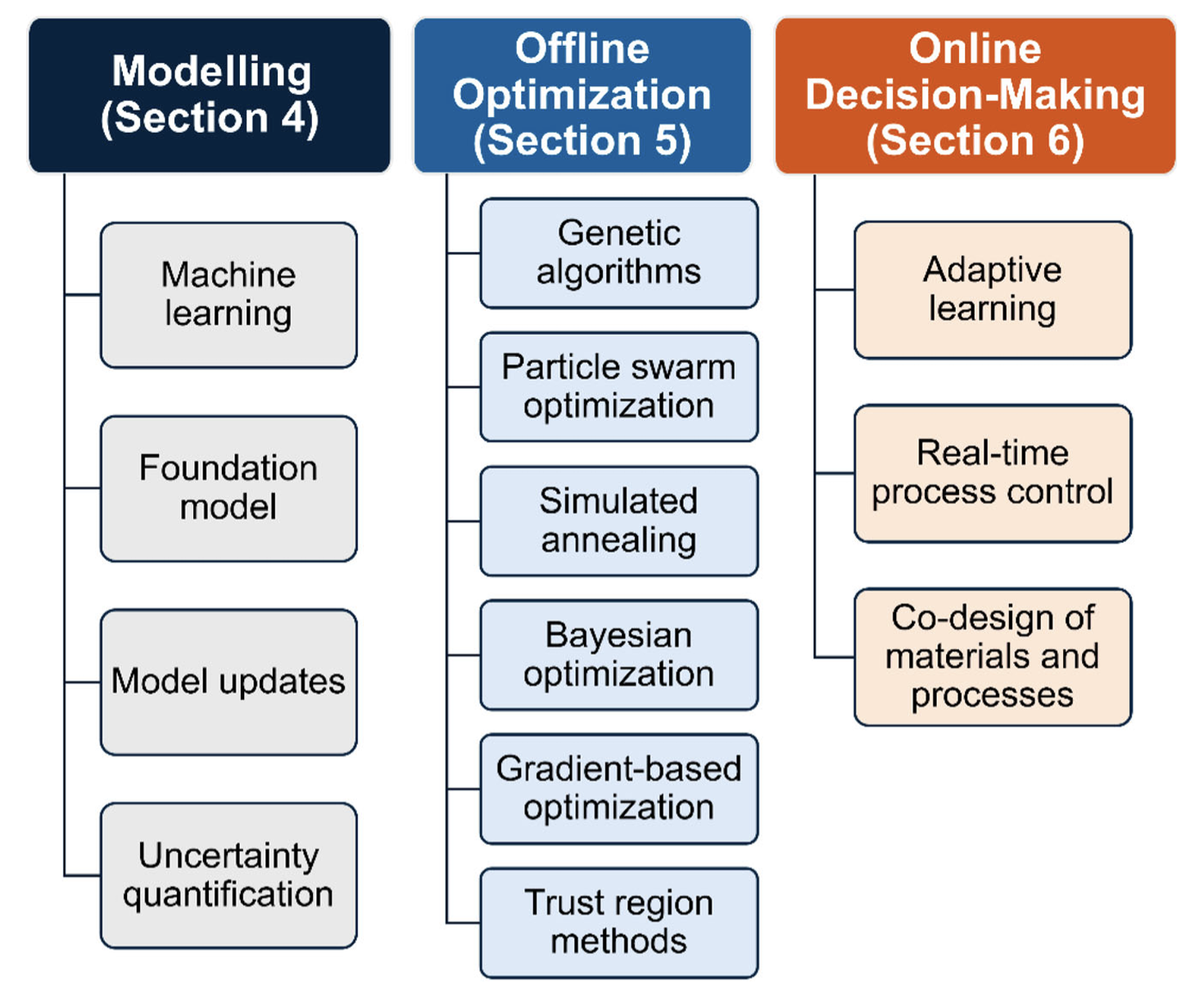

This article reviews optimization methods that enhance adaptability, efficiency and decision making in modern manufacturing, emphasizing the transformative role of artificial intelligence (AI) and digital twin technologies. By integrating AI and machine learning algorithms within digital twin frameworks, manufacturers can facilitate real-time monitoring, quality control and dynamic process adjustments. This synergy not only boosts operational efficiency but also enables precise modelling, offering predictive insights for strategic planning and innovation. The combination of digital twins and optimization techniques supports resource optimization, balancing competing objectives and driving continuous process improvements. With both offline and online optimization approaches, digital twins enable efficient production adjustments while ensuring long-term performance and scalability. Ultimately, this review highlights digital twins as foundational technologies for smart, sustainable manufacturing, incorporating advanced optimization strategies to enhance adaptability and operational resilience. This positions optimization algorithms and digital twins as key drivers in the future of intelligent production systems.

Keywords: Digital Twins, Optimization, Artificial Intelligent, Manufacturing Systems, Machine Learning

Recommended citation: Karkaria, V., Tsai, Y. K., Chen, Y. P., & Chen, W., "An Optimization-Centric Review on Integrating Artificial Intelligence and Digital Twin Technologies in Manufacturing." Engineering Optimization, 1-47 (2025).

Download Paper